THE NEW FACE OF MAINTENANCE REGULATION:

HOW EASA’S 2025 UPDATES ARE REDEFINING THE MRO LANDSCAPE

EASA’s 2025 reforms mark the start of a “predictive era” in MRO regulation, shifting maintenance from scheduled to data-driven and risk-based practices. New Airworthiness Directives and the mandatory Safety Management System (SMS) requirement embed predictive safety and real-time risk monitoring into daily operations. Though compliance costs rise, benefits include reduced unplanned maintenance, enhanced safety, and stronger digital integration. In this new framework, regulation becomes a driver of innovation, rewarding MROs that adapt quickly and use data intelligently.

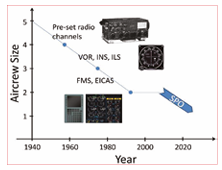

The European Union Aviation Safety Agency (EASA) has long been the guardian of airworthiness in the European aviation ecosystem. Yet, in mid 2025, the Agency initiated a new phase of transformation that goes beyond mere compliance checklists and dives deep into the operational DNA of maintenance organizations. Since July 2025, a series of critical Airworthiness Directives (ADs), procedural updates, and management requirements have marked the beginning of what many in the industry now call “the predictive era of MRO regulation” a landscape where maintenance is no longer only reactive or scheduled, but data driven, risk sensitive, and performance oriented.

This transformation’s first wave arrived through new technical revisions. Two directives, in particular, stand out for reshaping traditional maintenance cycles. EASA AD 2025-0142R1, for instance, withdrew previous maintenance instructions for a series of engine subassemblies after fatigue analysis revealed accelerated wear under variable load conditions. The practical implication for MROs was immediate: a mandate to revise maintenance task cards and check intervals, especially for medium haul aircraft using the affected components.

Similarly, AD 2025-0154R1 focused on wing-beam inspection, mandating repeat inspections for corrosion and micro-cracking at shorter intervals using enhanced non-destructive testing (NDT) techniques. This has already led several European carriers to update their heavy-check schedules, extending dock time by an average of 8–12 hours per aircraft. When EASA consolidated over 40 individual ADs across major fleets in its August Digest (Sass Sofia, 2025), the message became undeniable. Maintenance intervals are no longer just time or cycle based; they are fundamentally usage- and risk based. This transition represents the core of what EASA terms “condition driven airworthiness.”

Perhaps even more transformative than these technical shifts is the managerial and cultural revolution underway. Under Maintenance Annex Guidance (MAG) Change 10, all U.S. based Part 145 repair stations holding EASA approval must implement a fully operational Safety Management System (SMS) by December 31, 2025. This requirement expands far beyond procedural documentation; it embeds predictive safety intelligence into daily operations.

This new SMS mandate forces the integration of hazard identification and risk assessment (HIRA) directly into maintenance event planning. It requires mandatory data reporting channels between line maintenance teams and the accountable manager, coupled with continuous safety performance monitoring (SPM) using trend analysis. For EASA, this is a governance shift. Maintenance organizations must now measure safety as a performance variable tracking metrics like a Safety Risk Index (SRI) or Corrective Action Closure Rate (CACR) not merely as a passive outcome. In short, what gets measured, gets improved and now, safety itself is being measured.

The ripple effects of these regulatory updates are already being felt across the MRO ecosystem. The introduction of more frequent inspection cycles has increased average maintenance man-hours per aircraft by roughly 6–10%, according to early estimates. While this adds short term workload, it simultaneously enhances the predictive maintenance data pools that allow for better long term optimization. EASA’s push has also accelerated digitalization, with many organizations now integrating Maintenance Information Systems (MIS) with Flight Data Monitoring (FDM) to dynamically adjust inspection intervals. This, in turn, demands enhanced training. Maintenance engineers must now be as comfortable reading a dataset as they are reading a torque chart.

This leads to a new strategic and economic calculus. While compliance costs are projected to rise by 8–12% in the coming fiscal year, analysts expect a reduction in unplanned maintenance events by up to 20% by 2027. This reflects a crucial shift from a corrective to a preventive cost structure. Early adopters are already reaping tangible rewards; one Scandinavian MRO group reported a 15% reduction in annual safety audit observations after piloting a data driven SMS aligned with MAG 10, leading to lower insurance premiums. “Regulatory agility “ the ability to integrate new directives within 30 days versus the industry average of 90 is emerging as a powerful competitive differentiator.

Ultimately, EASA’s new framework forces a redefinition of what performance means in aviation maintenance. The next generation of MRO metrics must align technical reliability (like post maintenance defect rates) with regulatory responsiveness (such as average AD implementation time) and a robust organizational safety culture (measured by safety reporting participation).

By late 2025, the European maintenance sector stands at the threshold of an era where regulatory intelligence and data integration merge. EASA’s directives are no longer static constraints; they are dynamic inputs for continuous improvement. Forward-looking MROs are already embedding AI driven risk assessment tools into their planning and integrating SMS outputs directly into enterprise KPI frameworks.

This regulatory wave is more than an administrative update. It represents a philosophical realignment of aviation maintenance from rule following to risk forecasting, from corrective inspection to predictive assurance. Success in this new landscape will not be defined by how well organizations comply, but by how fast and intelligently they adapt. Regulation is no longer the ceiling; it is the framework for innovation.