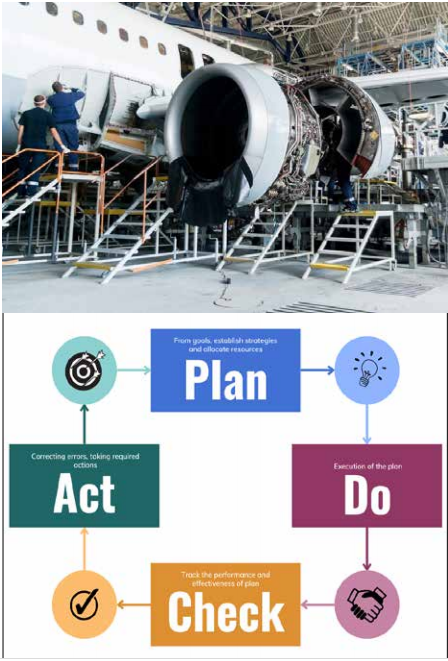

THE DEMING CYCLE AS A FRAMEWORK FOR CONTINUOUS IMPROVEMENT IN AVIATION QUALITY MANAGEMENT

Quality management is vital in high-reliability industries like aviation, where safety and precision are critical. The PDCA (Plan-Do-Check-Act) cycle, popularized by W. Edwards Deming, serves as a proven framework for continuous improvement. By emphasizing iterative learning and evidence-based process optimization, PDCA helps aviation maintenance organizations enhance safety, operational efficiency, and regulatory compliance. Integrating the Deming Cycle into organizational culture fosters a proactive approach to risk management, ensuring sustainable operational excellence and reinforcing passenger safety.

Quality management has become a cornerstone of modern organizations, particularly in high-reliability industries such as aviation, where safety, efficiency, and precision are paramount. One of the most influential thinkers in this field, W. Edwards Deming, famously asserted that “if you cannot describe what you are doing as a process, you do not know what you are doing.” This statement underscores the importance of structured processes in achieving organizational goals and ensuring consistent outcomes. Within this framework, one of the most enduring tools for continuous improvement is the PDCA cycle—also known as the Deming Cycle or Deming Wheel. The PDCA methodology was popularized by Deming in the 1950s during his work with Japanese industries, where it became a central driver of post-war industrial transformation and global competitiveness. The approach reflects a scientific method applied to management, emphasizing observation, experimentation, and iterative learning. Its lasting relevance lies in its adaptability, as it can be applied across a wide range of contexts, including manufacturing, healthcare, aviation maintenance, and service industries.

The PDCA model is a four-stage iterative process that enables organizations to introduce improvements in a systematic, evidence-based manner. It begins with the planning stage, where organizations identify what needs to be improved and set clear, measurable objectives. This requires a comprehensive understanding of current processes as well as the recognition of deficiencies, inefficiencies, or risks that must be addressed. In aviation, for example, planning may involve analyzing maintenance procedures to identify safety vulnerabilities. The next stage is implementation, where changes are introduced on a controlled, small scale. This trial approach allows organizations to test proposed improvements without exposing the entire system to potential disruptions. At the same time, employees must be adequately trained and provided with the necessary resources to ensure reliable execution. Once changes are implemented, their effectiveness is assessed through the evaluation stage, where outcomes are measured and compared against the objectives defined earlier. Data collection, monitoring, and analysis determine whether the improvements achieved the intended results. In industries such as aviation, this stage is particularly critical because compliance with international safety standards is mandatory. The final stage of the cycle is action. If the changes prove successful, they are standardized and integrated into routine operations. If the expected results are not achieved, corrective measures are introduced, and the process is redesigned. This reinforces the iterative nature of the cycle and ensures that improvement remains continuous rather than a one-time effort.

The Deming Cycle is not merely a theoretical model but also a practical tool with significant implications for sectors that demand precision and reliability. In aviation, continuous improvement is inseparable from the culture of safety. Aircraft maintenance organizations employ PDCA as a systematic framework to minimize human error, enhance process efficiency, and strengthen compliance with regulatory standards. Each iteration of the cycle helps cultivate a culture of learning and adaptability—an indispensable quality in environments where even minor mistakes may have critical consequences. The application of PDCA supports not only operational effectiveness but also proactive risk management, enabling organizations to anticipate and address potential failures before they escalate into threats to safety.

Ultimately, the PDCA cycle provides organizations with a structured methodology for achieving continuous improvement. Its iterative nature ensures that improvements are tested, validated, and standardized, thereby creating a sustainable framework for operational excellence. In aviation maintenance, applying the Deming Cycle not only enhances efficiency and reliability but also directly contributes to passenger safety and public trust. Embedding PDCA into organizational culture transforms improvement into an ongoing pursuit rather than an incidental effort, aligning with Deming’s philosophy that true quality management is a continuous journey of learning, adaptation, and accountability.