POWERING EFFICIENCY:

THE NO-BLEED SYSTEM ARCHITECTURE OF THE BOEING 787

The Boeing 787 Dreamliner features an architecture that largely replaces the pneumatic systems found in most conventional commercial aircraft with electrical systems. This innovative “no-bleed” system architecture reduces fuel consumption while increasing operational efficiency. The fundamental difference in the system’s architecture is the emphasis placed on electrical systems, which brings numerous advantages.

The Boeing 787 Dreamliner represents one of the most significant advancements in modern commercial aviation, introducing a revolutionary “more-electric” architecture that replaces many of the traditional pneumatic systems with electrical ones. Unlike conventional aircraft where bleed air taken from the engines powers systems such as cabin pressurization, air conditioning, or de-icing, the 787 eliminates the bleed manifold entirely and distributes electrical energy instead. This design change reduces the load on the engines, improves efficiency, and provides airlines with substantial benefits in terms of fuel savings, operational performance, and reliability.

Thanks to this innovative system, functions like air conditioning and wing ice protection are now powered electrically rather than pneumatically. The result is an increase in operational efficiency, with fuel consumption reduced by approximately three percent during flight. Since pneumatic systems require a portion of the high-pressure air generated by the engine, overall thrust efficiency is reduced, but in the electrical system this energy loss is eliminated. The engine can devote its full power to propulsion, which not only lowers fuel burn but also increases the aircraft’s range. The reduced number of moving parts and mechanical connections translates into lower maintenance requirements and higher system reliability, both of which contribute directly to reduced operating costs for airlines.

The no-bleed system architecture provides an additional one to two percent improvement in fuel consumption, especially noticeable during cruise, where power demands are highest. Instead of wasting excess compressed air as in conventional systems, electrical energy is distributed efficiently to where it is needed. This optimization of power use represents a fundamental step toward making long-haul operations more economical and sustainable.

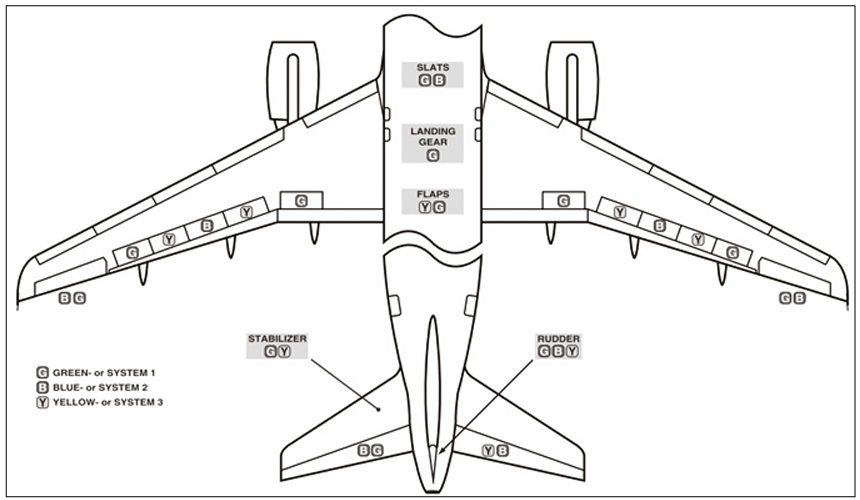

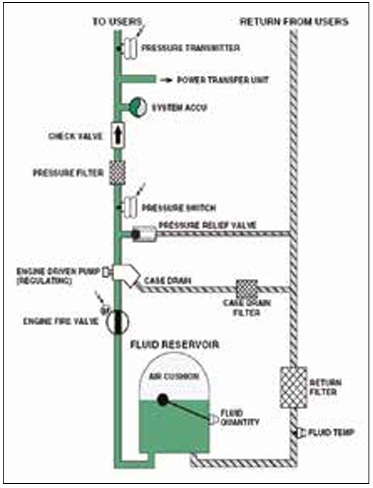

Hydraulic systems also benefit from the more-electric design. Rather than relying on large, air turbine-driven hydraulic pumps, the 787 employs pumps powered by electric motors. This approach increases efficiency throughout the flight while simultaneously achieving weight savings. By designing the hydraulic system to operate at higher pressures, smaller components could be used, reducing overall system weight and freeing valuable space within the aircraft. The result is an optimized balance between performance, efficiency, and structural design. Environmental control has likewise been redesigned around electrical power. Cabin pressurization and climate management are handled by variable-speed compressors driven by electric motors, which deliver only the precise level of pressure and airflow required at any given moment. This ensures efficiency while minimizing unnecessary energy consumption. The wing ice protection system has also undergone a dramatic transformation. Instead of using hot bleed air, the 787 employs electro-thermal heating blankets, which consume around fifty percent less energy compared to traditional systems. Beyond reducing energy demand, this system improves aerodynamic performance during flight by lowering drag, which further contributes to the overall efficiency gains of the aircraft.

At the heart of the Dreamliner’s innovation is a hybrid electrical network capable of operating at multiple voltage levels. Power generated by both the engines and the Auxiliary Power Unit is supplied as variable-frequency electricity and distributed across the aircraft. The modular architecture of this system makes power monitoring and distribution easier and more reliable, ensuring that essential functions are maintained under varying flight conditions. Importantly, the 787’s generators are designed to operate without constant-speed drives, which reduces system complexity, minimizes maintenance needs, and enhances reliability.

Together, these innovations establish the Boeing 787 as a landmark in the transition toward more-electric aircraft. The elimination of bleed systems in favor of electrical power offers a wide range of advantages, from reducing fuel consumption and extending flight range to lowering maintenance costs and increasing operational reliability. More importantly, this architecture supports the global drive for sustainability by cutting energy waste and lowering emissions, thereby benefiting not only airlines but also the environment. The Dreamliner’s no-bleed design is therefore more than just a technological innovation—it is a decisive step toward the future of commercial aviation, where efficiency, reliability, and environmental responsibility converge in one aircraft.