HOW AI IS REVOLUTIONIZING AIRCRAFT MAINTENANCE AND REPAIR INDUSTRY

Artificial Intelligence is transforming MRO from a reactive, manual process into a proactive, data-driven ecosystem. Through predictive maintenance, automated inspections, and generative AI copilots, aircraft downtime is minimized, safety is enhanced, and operational efficiency soars. By combining human expertise with intelligent automation, AI is not just optimizing maintenance it’s revolutionizing how aviation ensures reliability, safety, and profitability.

T

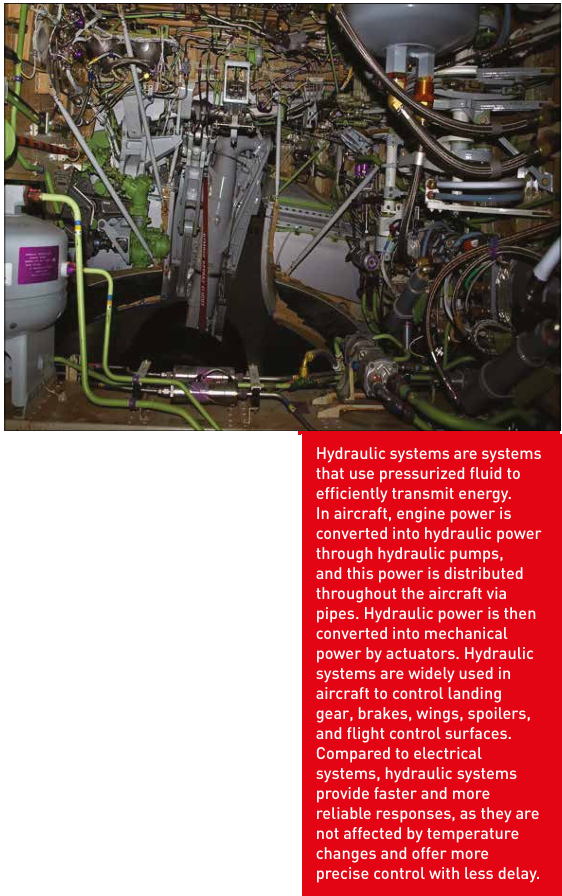

he aircraft maintenance and repair (MRO) industry is the unseen foundation of global aviation safety and efficiency. Traditionally reliant on fixed schedules, manual inspections, and paper-based logs, this sector has long faced challenges related to unexpected downtime, high operational costs, and the need for precision in a high-stakes environment. The advent of Artificial Intelligence (AI) and its associated tools is now creating a paradigm shift, moving the industry from a reactive model to a proactive, data-driven system. AI is primarily developing the MRO sector through two critical pathways: the adoption of predictive maintenance and the automation of complex inspection and diagnostic tasks.

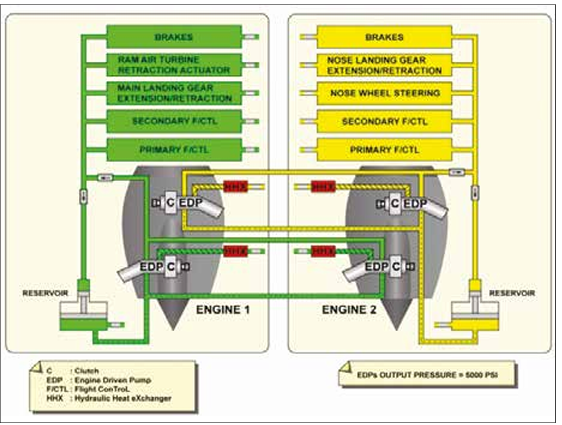

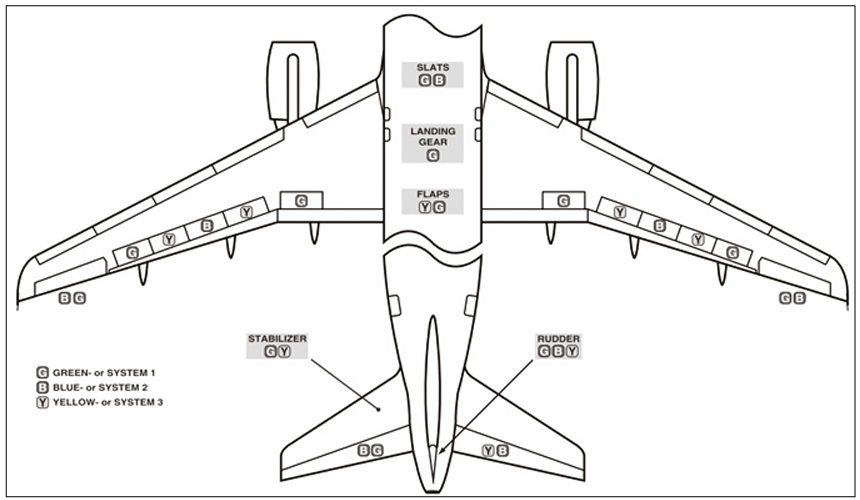

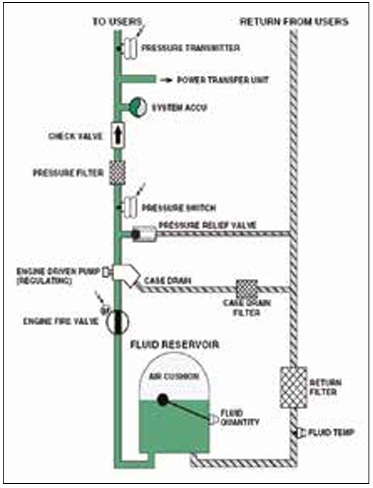

The most transformative application of AI is in Predictive Maintenance (PdM). Modern aircraft are equipped with thousands of Internet of Things (IoT) sensors that continuously generate massive volumes of data regarding the performance of critical components, such as engines, hydraulics, and avionics. AI-driven machine learning models analyze this “big data” in real-time to identify subtle anomalies or patterns that precede equipment failure. Unlike traditional maintenance, which dictates part replacement based on fixed flight hours, PdM forecasts the exact moment a component is likely to fail. This foresight enables maintenance teams to schedule interventions precisely when needed, thereby optimizing the lifespan of expensive parts, minimizing unnecessary inspections, and drastically reducing the risk of unexpected aircraft-on-ground (AOG) situations, which cost airlines millions.

In addition to intelligent forecasting, AI tools are also automating and enhancing physical maintenance processes. Computer vision systems, often mounted on autonomous drones, are now used to inspect the exterior surfaces of aircraft. These drones can complete a full fuselage inspection in minutes a task that typically takes aircraft maintenance technicians hours and their AI algorithms are trained to spot defects like tiny cracks, corrosion, or paint damage with greater consistency and accuracy than the human eye. Furthermore, Generative AI is streamlining administrative “busywork.” Maintenance Technicians can use conversational AI interfaces (often called “copilots”) to query maintenance manuals, troubleshoot complex issues, and automatically generate detailed maintenance log entries and work orders, converting hours of paperwork into minutes. Finally, AI dramatically improves resource allocation and supply chain efficiency. By predicting exactly which parts will be needed and when, AI-powered systems can optimize inventory management, ensuring critical components are available without the cost of overstocking. This enhanced operational efficiency, combined with significant cost savings from preventing unplanned downtime, is driving the widespread adoption of AI tools across the MRO ecosystem. In conclusion, AI is not merely optimizing the MRO industry; it is fundamentally redefining it, making air travel safer, more reliable, and ultimately more cost-effective.

Generative AI on the Hangar Floor:

A Technician’s Copilot

Generative AI (GenAI), such as large language models (LLMs), is being integrated into Maintenance, Repair, and Overhaul (MRO) operations to act as a real-time, knowledgeable assistant for Aircraft Maintenance Technicians (AMTs). Instead of replacing the technician, GenAI is augmenting their capabilities by minimizing manual “busywork” and accelerating troubleshooting. The primary role of GenAI is to provide context-aware, immediate access to structured and unstructured information, allowing technicians to spend more time performing maintenance tasks (often called “wrench time”) and less time on documentation and research.

The Virtual Troubleshooting Expert (“The Copilot”)

The most impactful application of GenAI is the creation of a “virtual expert” or AI Copilot. Technicians can now interact with a conversational chat interface to ask complex, technical questions.

Intelligent Documentation Retrieval: Maintenance manuals, service bulletins (SBs), airworthiness directives (ADs), and historical repair logs are typically unstructured and spread across thousands of pages. GenAI systems are trained on this vast corpus of documentation, allowing a technician to ask a natural language question (e.g., “What’s the procedure for resetting the hydraulic pump after an intermittent low-pressure warning on a Model X?”). The AI responds instantly with the exact, relevant section of the manual, often summarizing the steps. This process reduces documentation search time from hours to seconds.

Root Cause Analysis: When a reported fault is ambiguous (e.g., “Engine vibration detected”), the technician can describe the symptom to the copilot. The GenAI reviews historical data from similar faults across the fleet and suggests the most probable root causes, potential troubleshooting steps, and past successful resolutions, effectively coaching a less experienced AMT through a complex diagnosis.

Automated Reporting and Administrative Assistance

Technicians traditionally spend a significant portion of their shift on mandatory documentation, which is crucial for regulatory compliance but takes away from repair time. GenAI takes over much of this “busywork.”

Automated Work Log Generation: After a repair is complete, the technician can dictate their actions via voice or enter a few bullet points. The GenAI instantly generates a structured, compliant maintenance report, correctly classifying the work performed and filling in required technical data (like ATA chapters) based on the context.

Automatic Part Ordering: Once a technician determines a part needs replacement, the copilot can automatically generate and submit the necessary work orders and purchase orders, checking against current inventory and compliance rules without manual data entry.

Visual and Multimodal Inspection Assistance

GenAI systems are evolving beyond text to process images and video, adding another layer of efficiency to the inspection process.

Image-Based Query: Instead of typing a description of a component, a technician can take a picture of a complex assembly or a damaged part. The GenAI instantly recognizes the component, matches it to the correct diagram in the maintenance manual, and retrieves the relevant inspection procedure or repair instruction.

Component Recognition and Validation: During a procedure, the AI can use computer vision to ensure the technician is working on the correct part. For safety-critical steps (like torque settings), the system can provide real-time visual validation, ensuring 100% adherence to the documented procedure and reducing human error.

Enhanced Training and Upskilling

Given the projected shortage of experienced AMTs, GenAI is vital for rapidly bringing new technicians up to speed.

Customized Training Materials: GenAI can take standard, complex maintenance protocols and automatically generate customized, simplified training guides, step-by-step videos, or interactive quizzes tailored to the experience level of the trainee.

On-the-Job Knowledge Transfer: The “copilot” acts as a persistent mentor, providing instant access to the collective knowledge of the organization, ensuring that expertise from retiring veterans is codified and immediately available to the next generation of technicians. This framework highlights how GenAI is moving maintenance from a reactive, document-heavy process to a proactive, highly efficient, and human-centric workflow.

The adoption of Artificial Intelligence (AI) in aviation Maintenance, Repair, and Overhaul (MRO) promises huge gains in efficiency and predictive maintenance. However, given the safety-critical nature of the sector, AI systems face severe supervision. Integrating AI requires overcoming three core areas of challenge: regulatory approval (EASA/FAA/NAA), technical model assurance, and ethical/operational concerns.

Nowadays, so many tools generated by Artificial Intelligence have been utilized in MRO Industry. Revised safety enhancements and minimized downtime. The application of AI in aviation maintenance has the capability to avert unexpected repairs, thus lessening the chances of aircraft being grounded and delays in flight schedules. Furthermore, real-time predictive maintenance powered by AI allows for the early identification of possible problems, enabling timely interventions before they turn into safety risks.

AI-driven algorithms assist airlines in accurately predicting potential complications, such as equipment malfunctions and maintenance requirements. They accomplish this by examining extensive datasets derived from aircraft systems, sensors, and past maintenance history. Consequently, this leads to a decrease in unscheduled maintenance and reduces the time aircraft spend out of service. So, AI improves safety and reduces downtime. At the same time AI provides cost-effective maintenance management by detecting all faults in the aircraft system and analyzing historical maintenance data to predict the demand for components or parts. Besides them, AI empowers decision-making and workload optimization and generates in-depth analysis and reporting.

In summary, while the technology is powerful, the industry must fundamentally shift its safety assurance philosophy moving from certifying deterministic products to validating adaptive processes that involve continuous monitoring and human-AI collaboration. This necessity for robust testing, transparency, and collaboration among regulators, airlines, and tech providers is what makes AI adoption in aviation maintenance so challenging and critical.