BASIC HYDRAULIC SYSTEMS IN MODERN AIRCRAFT

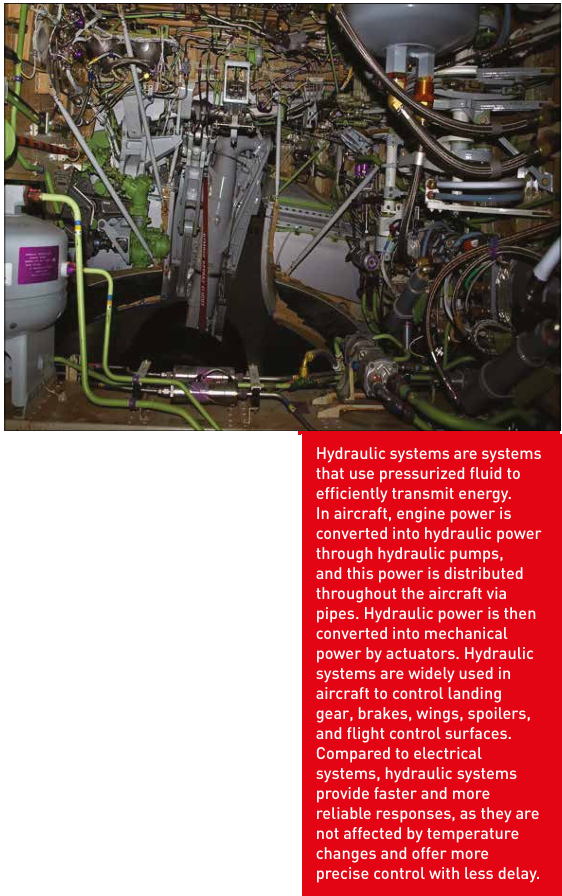

In aircraft, hydraulic systems are systems that use pressurized fluids to efficiently transmit energy. These systems draw power from the engines and convert it into hydraulic energy. Hydraulic systems are used to control various aircraft functions, including landing gear, brakes, wings, spoilers, and flight control surfaces.

What is a Hydraulic System?

Aircraft hydraulics is a system that transmits energy or power efficiently from one point to another using pressurized fluid. Hydraulic systems take engine power and convert it into hydraulic power through a hydraulic pump. This power can be distributed throughout the aircraft via hydraulic lines. Hydraulic power can be reconverted into mechanical energy via an actuator or turbine.

Hydraulic systems are widely used in aircraft to control structures such as landing gear, brakes, wings, spoilers, and flight control surfaces. In basic terms, a hydraulic pump converts mechanical power into hydraulic power. An actuator cylinder, or simply actuator, converts hydraulic power into mechanical power. If an electrical system were used instead of a hydraulic system, the pump would be replaced by a generator and the actuator cylinder by a motor.

An actuator can convert hydraulic power into linear or rotational motion. It includes a reduction gear to lower the rotational speed to the required amount. A flight control surface must respond instantly to inputs, which a hydraulic system can easily achieve. In an electric system, a rotating armature must come to a complete stop and then reverse direction; otherwise, it could burn out. In a hydraulic system, this issue does not arise as it doesn’t require a motor.

In a landing gear, a hydraulic motor can generate sufficient power to retract or extend the gear even under aerodynamic loads and air resistance. Previously, systems used steel cables connected through pulleys between the control mechanism (like pedals) and control surfaces (like rudders). These cables were affected by temperature-induced expansion. Hydraulic systems, being closed systems (not exposed to the atmosphere), are not influenced by temperature in the same way, enabling more reliable movement. This allows for better aircraft control and reduced response delay between pilot input and control surface reaction.

Advantages and Disadvantages of Hydraulic Systems

Advantages:

Hydraulic systems in aircraft offer several advantages compared to pneumatic, electric, and mechanical systems. For instance, they have a high power-to-weight ratio, meaning a small and lightweight pump and actuator can produce a large amount of force and torque. This not only reduces system weight and size but also enhances aircraft performance and fuel efficiency.

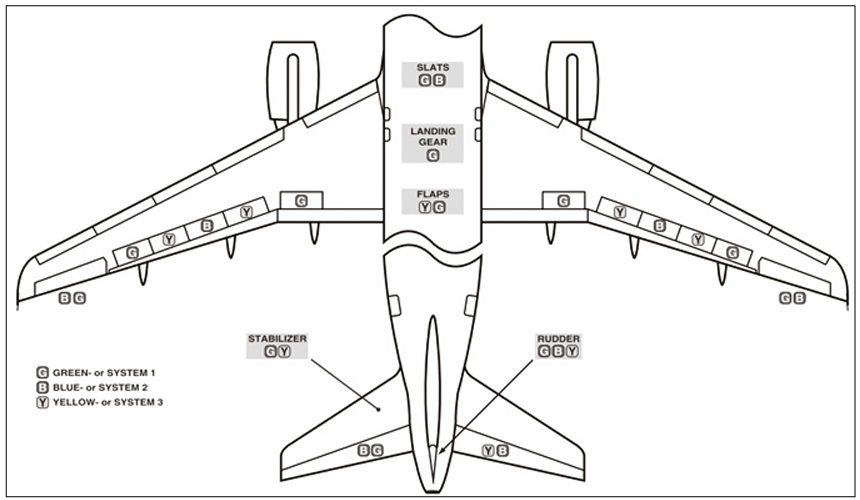

Additionally, hydraulic systems are highly flexible and adaptable, allowing for easy configuration and modification to suit different functions and requirements. They can also be integrated with electronic and computer systems to improve control and feedback. Moreover, hydraulic systems provide high safety and redundancy due to multiple fail-safe features, such as pressure regulators, relief valves, accumulators, and dual or triple pump configurations. These features ensure system safety and reliability during failures or emergencies and allow operation at reduced or partial capacity when necessary. They can respond quickly to demand and practically generate unlimited power.

Disadvantages:

Hydraulic systems require pumps, reservoirs, actuators, valves, and fluid lines, which increase weight. More components mean higher maintenance and complexity. Leaks can reduce system efficiency and lead to failures. Hydraulic fluids under high pressure are flammable and increase fire risk. Leaks and pressure loss require regular inspection. Fluid contamination may cause component wear, corrosion, or failure. Spilled hydraulic fluid poses environmental hazards and is difficult to clean. Disposal of used fluid requires waste management and strict environmental regulations.

Fluid friction generates heat, necessitating cooling systems. Excessive heat can degrade fluid properties and reduce system performance. Hydraulic pumps can be noisy and contribute to cabin noise. High-pressure fluid flow may cause vibrations, affecting comfort and component wear. Hydraulic systems consume energy even when not in active use. Seals, hoses, and pumps degrade over time and require periodic maintenance. High-pressure systems may cause fatigue and wear in metal components.

Hydraulic System Components

Hydraulic systems are essential in modern aircraft to operate various critical components requiring high force and precision. These include landing gear extension/retraction, movement of main and secondary flight control surfaces (aileron, elevator, rudder, spoilers, and flaps), braking systems, and cargo doors.

In most modern aircraft, major components such as accumulators, engine-driven hydraulic pumps, electric pumps, reservoirs, filters, relief valves, fill valves, and related equipment are centralized in easily accessible hydraulic service bays for routine maintenance.

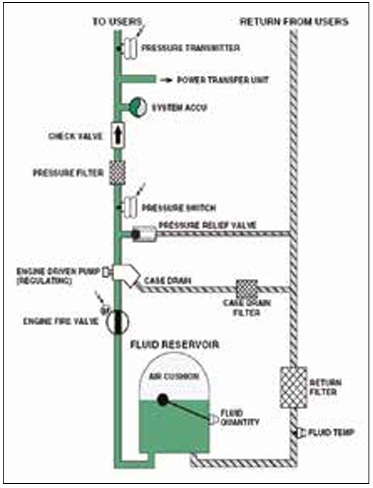

The reservoir in a basic hydraulic system stores hydraulic fluid, usually mineral- or synthetic-based. The pump draws fluid from the reservoir and pressurizes it, sending it to a valve. The valve regulates flow and direction of fluid to the actuator, which converts hydraulic pressure into mechanical motion and may be a motor or servo. The fluid then returns to the reservoir through a filter and cooler.

In case of fire, fire shutoff valves in the cockpit can cut off all flow (fuel, hydraulic, air). These valves may be located in the supply lines of pumps in every aircraft type.

A pressure switch warns the cockpit if pump pressure is too low by activating a low-pressure light. A pressure relief valve opens when pressure is too high to protect the system or components from damage. A pressure filter removes contaminants or metal particles from hydraulic fluid to prevent system failure. A check valve prevents fluid from flowing back to the pumps crucial in case of pump or engine failure in flight.

After passing through check valves, the fluid goes to a manifold. The hydraulic manifold is a metal block onto which flight control and landing gear system components are mounted. The fluid is routed to system parts via distribution ports. Typically, pressure relief valves, system pressure sensors, and switches are mounted on the manifold.

To reduce pressure spikes or dampen fluctuations, nitrogen-charged accumulators are used. The fluid returns to the reservoir via a return line and return filter, forming a closed-loop main system.

The case drain collects small internal leakage flow and returns it to the reservoir via a filter and sometimes a temperature sensor. The case drain filter must be checked frequently as it cools the pump bearings and indicates potential bearing failure. An increase in case drain temperature may signal internal leakage, which can lead to fluid overheating and performance loss.

Hydraulic Fluids

Aircraft systems use hydraulic fluids based on vegetable, mineral, or synthetic oils with the following characteristics:

Provide adequate lubrication.

Viscosity must be low enough to minimize friction in pipes and allow high-speed pump/motor operation, but high enough to prevent leakage and reduce fluid weight.

Prevent internal corrosion.

Operate across a wide temperature range.

Fluids are color-coded for identification.

Unless stated otherwise in the AMM, fluids with different properties must never be mixed.

During servicing, it is essential to follow current AMM procedures.

Phosphate-ester-based synthetic fluids are commonly used in modern aircraft due to their fire resistance and wide operating temperature range. Skydrol and Hyjet are the most commonly used hydraulic fluids.

Hydraulic System Pumps

Pumps pressurize the hydraulic fluid. Generally, there are three types of pumps in a hydraulic system: Engine Driven Pumps (EDP), Electric Motor Pumps (EMP), and Hand Pumps.

Engine Driven Pumps (EDP):

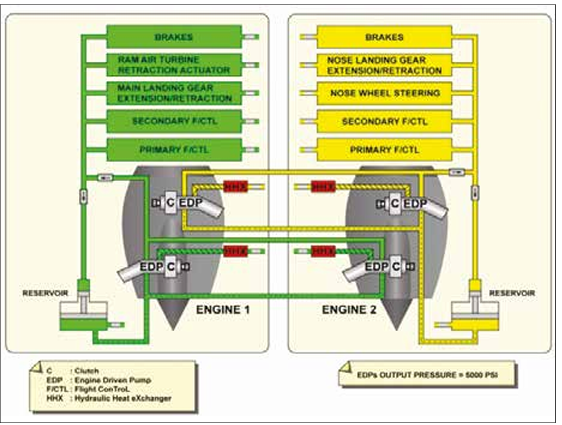

In twin-engine aircraft, each engine has a pump that supplies flow and pressure to the hydraulic power system. These are the main pumps or engine-driven pumps. They are usually variable displacement pumps, which adjust flow and pressure without needing a pressure regulator. A large-diameter supply line, pressurized reservoir, and minimal components between the reservoir and pump (except fire shutoff valve) are essential for proper supply.

The EDP is the primary source of hydraulic power and is mounted on the engine accessory gearbox, driven by the engine. Its speed depends on engine RPM higher RPM increases pump speed and flow, and vice versa. Aircraft manuals specify two flow values: at idle and at maximum engine thrust.

Most modern aircraft (A320, B737NG/MAX) operate at 3,000 psi hydraulic pressure. Advanced aircraft like the Boeing 787 use systems operating at 5,000 psi to reduce weight and improve efficiency.

Electric Motor Pumps (EMP):

Used mainly for ground servicing and maintenance (e.g., operating cargo doors). May be gear or variable piston type. In some aircraft, they act as main or backup pumps, operating continuously and supplying fluid to their hydraulic systems. Powered by the aircraft’s three-phase electrical system, EMPs are typically located near landing gear bays. Most aircraft have two electric pumps, which require cooling fans.

Hand Pumps:

Some aircraft have manual hand pumps for emergency use or ground operations. These are dual-action pumps (deliver fluid on both strokes). As the piston moves upward, fluid enters the cylinder through a non-return valve (NRV). Simultaneously, fluid above the piston is discharged through a check valve. On the downward stroke, the inlet valve closes, and the transfer valve opens to allow fluid to move through the piston and discharge the excess via the outlet. If outlet pressure exceeds a set safety valve threshold, the discharged fluid is redirected to the inlet.