ADVANCING THE BOUNDARIES OF TURBOFAN TECHNOLOGY:

MATERIAL AND DESIGN INNOVATIONS IN THE LEAP ENGINE

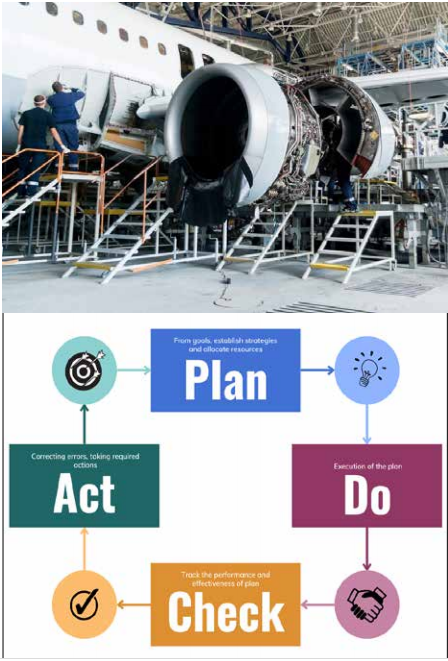

CFM International, a 50–50 joint venture between GE and Safran, developed the LEAP engine as a modern successor to the CFM56 series. The LEAP-1A, -1B, and -1C power the Airbus A320neo, Boeing 737 MAX, and COMAC C919, respectively. Featuring advanced technologies such as composite fan blades, blisk compressors, TAPS II combustors, CMC materials, and 3D-printed fuel nozzles, the LEAP engine is 226 kg lighter, 15% more fuel-efficient, and significantly cleaner and more durable, offering faster 25-minute turnaround times.

T

he CFM company is a 50–50 joint venture between the American company GE (General Electric) and the French company Safran. The CFM56-5A/B engines are used on the Airbus A320 family, the CFM56-5C engines on the A340 aircraft, the CFM56-7B engines on the Boeing 737-800, and the CFM56-3 engines on the Boeing 737-400. The LEAP engines can be described as a modernized version of the widely used CFM56 series. The LEAP-1B version powers the Boeing 737 MAX, the LEAP-1C version powers the COMAC C919 (Commercial Aircraft Corporation of China), and the LEAP-1A version is used on the Airbus A320neo. The acronym LEAP stands for “Leading Edge Aviation Propulsion.” In the LEAP program, Safran is responsible for the air inlet section, low-pressure turbine (LPT) section, oil system, accessory drives, and engine indicating system, while GE is responsible for the high-pressure compressor (HPC) section, high-pressure turbine (HPT) section, combustion diffuser section, fuel and control system, air system, ignition system, and starting system. The core architecture of the lighter and more durable LEAP engine includes a scaled-down version of the low-pressure turbine used in the GEnx engine. The fan section has 18 composite fan blades with titanium leading edges, manufactured using 3D woven RTM (Resin Transfer Molding) technology, making them lighter and much more durable. Each engine is approximately 500 lbs (around 226 kg) lighter than its predecessors. The bypass ratio of the engine is about 9:1. The N1 shaft rotates at approximately 4,500 RPM, while the N2 shaft spins at 20,000 RPM.

Although the LEAP engine was designed to operate at higher pressures than the CFM56 (to achieve greater efficiency), the operating pressure is intentionally kept below maximum limits to maximize service life and reliability. The high-pressure compressor (HPC) uses “blisk” (bladed disk) technology. In the combustion chamber, second-generation Twin Annular Pre-mixing Swirler (TAPS II) burners are used, resulting in about a 50% reduction in NOx emissions. The bearing section incorporates ceramic hybrid bearings, which are 40% lighter and longer-lasting. For the first time in this engine type, 3D printing (additive manufacturing) was used to produce fuel nozzles, making them about 25% lighter. Ceramic Matrix Composites (CMC) are used in the turbine shrouds; these materials withstand higher temperatures compared to conventional alloys and reduce the need for cooling airflow. The engine achieves an approximate 15% improvement in fuel efficiency. Additionally, the LEAP engine supports a 25-minute ground time (gate turnaround time), providing a significant operational advantage over competitors.