THE NECESSITY OF EFFECTIVE USE OF TROUBLESHOOTING MANUALS BY AIRCRAFT MAINTENANCE TECHNICIANS TO SOLVE AIRCRAFT SYSTEM FAILURES

Troubleshooting Manual (TSM) is a technical guide used by Aircraft Maintenance Technicians (AMTs) to systematically identify and resolve issues in aircraft systems. It offers step-by-step instructions, flowcharts, and tests for diagnosing and repairing problems in mechanical, electrical, avionics, and hydraulic systems. These manuals are crucial for ensuring accurate fault isolation, safety, and compliance with regulations.

What is Troubleshooting?

A troubleshooting manual (TSM) is a technical document that aircraft maintenance technicians (AMTs) use to systematically find, identify, and fix problems in aircraft systems. It provides step-by-step instructions for isolating problems, flowcharts, and tests to help technicians efficiently identify and repair issues in mechanical, electrical, avionics, and hydraulic systems. Aircraft Maintenance Technicians (AMTs) rely on Troubleshooting Manuals (TSMs) or Fault Isolation Manuals to efficiently diagnose and resolve technical issues in aircraft systems. These manuals are essential because they provide a structured, step-by-step approach to identifying and fixing faults, ensuring safety, accuracy, and regulatory compliance.

Steps of the Troubleshooting Process for Aircraft Maintenance Technicians

The troubleshooting process follows a systematic approach to identify and resolve aircraft malfunctions. Here are the essential steps:

Identify the Problem 2?Gather information from pilots, maintenance logs, and fault messages.

Understand the System 2?Review aircraft manuals (AMM, TSM, FIM) and system schematics.

Collect Data 2? Use diagnostic tools, Built-In Test Equipment (BITE), and Centralized Fault Display System (CFDS) messages.

Analyze Possible Causes 2?Narrow down the issue by checking related components and previous occurrences.

Develop a Troubleshooting Plan 2 ? Follow logic trees, decision-making flowcharts, and system tests.

Test and Verify the Fault 2Conduct system tests and isolate the faulty component.

Apply the Corrective Action 2?Repair or replace the defective part.

Verify the Solution 2Perform operational tests to ensure the issue is resolved.

Document the Process 2 Record findings, corrective actions, and test results for compliance and future reference.

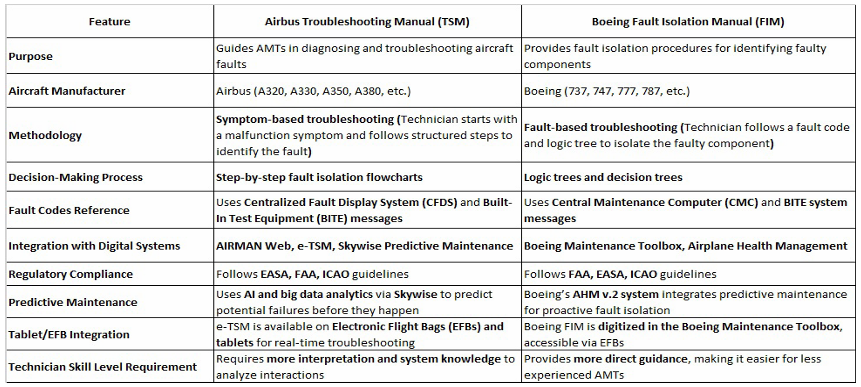

Airbus and Boeing Concept

Aircraft manufacturers publish documents that must be kept up to date for important tasks such as aircraft maintenance and repair. Airbus uses the Troubleshooting Manual to solve problems in aircraft systems, while Boeing uses the Fault Isolation Manual. For instance, The Airbus Aircraft Family’s maintenance philosophy is based on the Centralized Fault Display System (CFDS) and Troubleshooting Manual (TSM). It consists of two levels: component replacement and troubleshooting at line and main base.

The Centralized Fault Display System (CFDS) is designed to simplify maintenance tasks by showing fault messages in the cockpit and allowing the flight crew to perform specific tests. The CFDS directly monitors and diagnoses problematic Line Replaceable Units (LRUs) in aviation systems, displaying the identified items to the maintenance crew. This is accomplished primarily through an analysis of all cockpit events generated by aircraft system monitoring. The CFDS additionally assists in preventing improper equipment removals by doing a detailed analysis to identify the responsible LRUs.

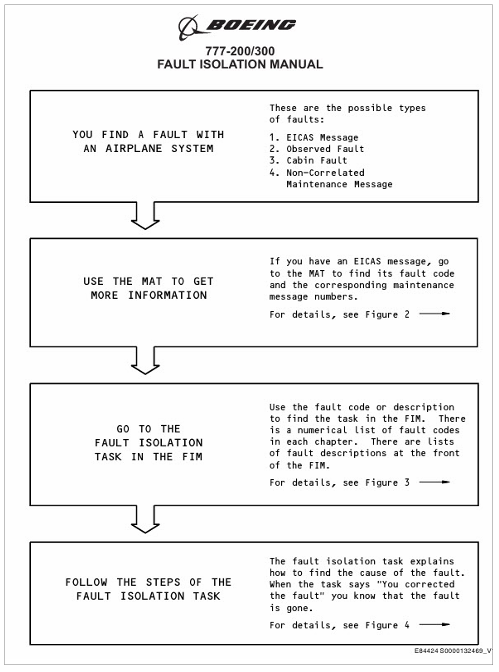

On the other hand, The Boeing Standard Fault Isolation Practices describe the processes and principles used to identify and eliminate defects on Boeing aircraft. This is typically described in a Fault Isolation Manual (FIM). The FIM is a valuable tool for maintenance staff because it provides a methodical approach to troubleshooting and isolating issues in the aircraft’s systems and components. It is designed to guide the technician from the general problem to the specific faulty component by following a logical troubleshooting process.

Boeing has created an Interactive Fault Isolation Manual (IFIM) to make it easier to discover and fix defects. This interactive manual is part of Boeing’s continued commitment to providing efficient and effective solutions for aircraft troubleshooting and maintenance. The IFIM is a web-based program that makes it easier to discover the appropriate fault isolation task for a specific defect and then displays it in an easy-to-follow format.W

Key Reasons Utilizing TSM or FIM During Aircraft Maintenance

Airworthiness and Safety

Aircraft safety is the most important thing in aviation and these manuals help AMTs ensure that all systems function correctly. By following the TSM, technicians can systematically diagnose and eliminate faults before they cause serious problems. TSMs provide verified procedures that minimize the risk of incorrect repairs that could compromise safety ensuring proper repairs. Aviation authorities (FAA, EASA, ICAO) require maintenance procedures to follow standardized troubleshooting guidelines to maintain airworthiness.

Systematic Approach to Fault Diagnosis

Aircraft are complex machines with thousands of interconnected systems. Troubleshooting manuals help AMTs follow a logical process to find and fix faults efficiently. TSMs provide flowcharts, fault isolation procedures, and guided tests to narrow down the root cause of a malfunction enabling step-by step troubleshooting. Instead of guessing or using trial and error, AMTs can methodically rule out possible causes, saving time and effort, in other words, efficient problem-solving. Following structured troubleshooting procedures ensures that AMTs do not overlook critical details or make costly mistakes.

Reducing Aircraft Downtime and Maintenance Costs

Airlines and operators aim to keep aircraft operational and minimize the time spent on maintenance. TSMs contribute to achieve this by streamlining troubleshooting processes. By following the TSM, technicians can quickly determine the issue, reducing delays in getting the aircraft back in service. Proper troubleshooting prevents the unnecessary replacement of components, which can be costly and time-consuming. AMTs can efficiently allocate manpower, tools, and spare parts by using the TSM’s guidance to target the actual issue and thus optimizing resource use.

Improving Technician Efficiency and Knowledge

TSMs serve as an essential learning resource for both new and experienced AMTs. By using TSMs regularly, technicians improve their diagnostic abilities and troubleshooting efficiency. Aircraft manufacturers update TSMs regularly to incorporate new technologies and troubleshooting methods. Many aviation maintenance training programs use TSMs to teach technicians standardized troubleshooting techniques.

Supporting Preventive and Predictive Maintenance

Troubleshooting manuals enables AMTs detect early signs of potential failures, enabling proactive maintenance. By analyzing historical fault data in TSMs, technicians can address underlying issues before they cause significant problems so preventing future failures. Proper troubleshooting reduces repeat failures, improving overall aircraft performance and reliability. TSMs encourage AMTs conduct predictive maintenance by identifying trends and common failure points reducing unscheduled maintenance.

Complementary Factors Using These Manuals in Operation

Assisting in Troubleshooting Complex Systems

Modern aircraft have advanced avionics, fly-by-wire controls, and automated diagnostic systems that require precise troubleshooting techniques. Many aircraft have self-diagnostic systems that provide error codes by using Built-In Test Equipment (BITE). TSMs aids technicians interpret these codes and determine corrective actions. A failure in one system can affect others in interconnected system analysis. TSMs provide AMTs understand system interdependencies and locate faults efficiently.

The manuals guide technicians on how to use specialized diagnostic tools such as multimeters, oscilloscopes, and hydraulic testers for accurate diagnosis.

Enhancing Regulatory Compliance

Aviation maintenance is strictly regulated by organizations like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). Airlines and maintenance providers must follow approved procedures outlined in TSMs to maintain compliance to meet legal requirements. Many TSMs include documentation guidelines that ensure accurate maintenance recording of faults and repairs, which is essential for audits and inspections. Failure to follow correct troubleshooting procedures can result in fines, legal action, or loss of maintenance certification so this avoids regulatory penalties.

Standardizing Maintenance Procedures

Aircraft manufacturers, such as Boeing, Airbus, and Embraer, develop Troubleshooting Manuals to ensure all AMTs follow the same diagnostic procedures worldwide. Regardless of location, all technicians use the same structured approach to troubleshooting, ensuring reliable results. TSMs are created based on extensive testing and engineering data, ensuring that AMTs follow the correct procedures. Standardized troubleshooting steps creates easy communication among technicians across different shifts or locations understand and continue the work seamlessly.

Qualifications Required for Aircraft Maintenance Technicians to Use Troubleshooting Manuals

To properly utilize these manuals, AMTs must possess a combination of education, certification, practical experience, technical skills, and soft skills.

Educational Background

A strong educational foundation is crucial for AMTs to understand aircraft systems and troubleshooting procedures. The minimum educational requirement is typically a high school diploma or its equivalent, with a focus on mathematics, physics, and technical subjects. Many AMTs further their education by attending an aviation maintenance program at an FAA- or EASA-approved school (especially PART-147 Basic Training), where they receive structured training in areas such as: Aircraft structures and aerodynamics, Powerplant systems (engines and propulsion), Avionics and electronic systems, Hydraulic, pneumatic, fuel systems etc. These programs equip AMTs with theoretical knowledge and practical experience in maintaining and troubleshooting aircraft.

Certifications and Licensing

To work as an AMT and use troubleshooting manuals effectively, technicians must obtain the necessary certifications and licenses. These certifications ensure that AMTs meet industry standards and regulatory requirements. The primary certifications include:

FAA Airframe and Powerplant (A&P) Certificate required in the U.S., qualifies AMTs to perform maintenance, inspections, and repairs on aircraft systems.

EASA Part-66 License: In Europe, AMTs must obtain a Part-66 license, categorized into different levels (e.g., B1 for mechanical, B2 for avionics, and B1/B2 combined for both).

Other Regional Certifications: Various aviation authorities worldwide, such as CASA (Australia), CAAC (China), and DGCA (Türkiye), have similar certification requirements. These certifications validate an AMT’s ability to interpret and apply troubleshooting procedures outlined in manuals like the TSM or FIM.

Practical Experience

While theoretical knowledge is essential, hands-on experience is equally important. Most aviation regulatory bodies require AMTs to complete a set number of hours in practical training before they can be certified. On-the-job training (OJT) helps technicians develop their skills in:

Diagnosing system malfunctions using troubleshooting manuals

Utilizing aircraft diagnostic tools and software

Conducting fault isolation and performing corrective actions

Working with specific aircraft models (e.g., Boeing 737, Airbus A320)

Practical experience enhances an AMT’s ability to navigate troubleshooting manuals efficiently and make accurate maintenance decisions.

Technical Skills

To effectively use troubleshooting manuals, AMTs must possess a range of technical skills, including:

Reading and Interpreting Technical Documentation: AMTs must be able to understand complex schematics, wiring diagrams, and flowcharts presented in troubleshooting manuals.

Diagnostic Proficiency: The ability to systematically analyze symptoms, use Built-In Test Equipment (BITE), and interpret fault messages from onboard aircraft systems.

Use of Specialized Tools: AMTs must be skilled in using multimeters, oscilloscopes, hydraulic testers, and software-based diagnostic tools.

Computer Literacy: Many troubleshooting manuals are now digital (e.g., Boeing Maintenance Toolbox, Airbus e-TSM), requiring familiarity with computer-based maintenance tools.

Soft Skills

In addition to technical expertise, AMTs must develop essential soft skills to work efficiently with troubleshooting manuals and within a team. Key soft skills include:

Problem-Solving Ability: Troubleshooting manuals provide structured guidance, but AMTs must use logical reasoning and experience to diagnose and fix issues accurately.

Attention to Detail: Even minor errors in reading or interpreting troubleshooting procedures can lead to incorrect diagnoses and safety risks.

Communication Skills: AMTs must document maintenance actions clearly and communicate findings with engineers, pilots, and other technicians.

Adaptability and Continuous Learning: Aviation technology is constantly evolving, requiring AMTs to stay updated on new troubleshooting methods and system advancements

Specialized Training and Type Training

Some AMTs undergo type-rating training, which provides in-depth knowledge of specific aircraft models. Airlines and maintenance organizations often require AMTs to complete type-specific training for aircraft like the Boeing 787 or Airbus A350. This training includes:

Advanced troubleshooting techniques tailored to a specific aircraft type

Hands-on training with real-world fault scenarios

Understanding how different aircraft systems interact in troubleshooting procedures

Type ratings and specialized training significantly enhance an AMT’s ability to efficiently use troubleshooting manuals for aircraft maintenance.

Aircraft Maintenance Technicians utilize Troubleshooting Manuals (TSMs) because they provide a structured, accurate, and standardized approach to diagnosing and fixing aircraft issues. These manuals enhance safety, efficiency, compliance, and cost-effectiveness, making them an indispensable tool in aircraft maintenance. By following TSM or FIM procedures, AMTs ensure that aircraft remain airworthy, reliable, and operational, ultimately contributing to the overall safety and efficiency of the aviation industry.