OPTIMIZING AIRCRAFT MAINTENANCE

CONCEPTS, DETAILED METHODOLOGIES, AND FUTURE DIRECTIONS

Aircraft maintenance optimization is at the heart of modern aviation, balancing safety, operational efficiency, and cost management. With increasing fleet sizes, stringent regulatory requirements, and the rising complexity of aircraft systems, maintenance optimization has evolved from simple reactive repairs to sophisticated data-driven strategies.

This paper delves into the evolution of maintenance methodologies, the contributions of Reliability-Centered Maintenance (RCM) and the Maintenance Steering Group (MSG) frameworks (MSG-1, MSG-2, MSG-3), and the integration of advanced technologies like Airplane Health Monitoring (AHM) and digital twins. Furthermore, it discusses future directions and the critical role of artificial intelligence (AI) and machine learning (ML) in predictive maintenance.

From Corrective to Reliability-Centered Approaches

Aircraft maintenance has evolved significantly from its early days of reactive repairs to today’s highly structured and reliability-focused methodologies. Initially, the industry operated under a “fix-it-when-it-breaks” philosophy, known as corrective maintenance. While straightforward, this approach proved costly, inefficient, and posed significant safety risks. As jet aircraft became more complex in the mid-20th century, the need for structured maintenance programs became evident.

By the 1960s, preventive maintenance became the dominant strategy, with components overhauled at fixed intervals based on historical failure data. However, this often resulted in unnecessary maintenance of fully functional components, leading to increased costs and operational inefficiencies. To address these challenges, the 1970s saw the introduction of Reliability-Centered Maintenance (RCM), which revolutionized aircraft upkeep by systematically analyzing failure mechanisms. RCM prioritizes critical systems affecting safety and operations, identifies failure modes and their consequences, and tailors maintenance tasks to mitigate failures cost-effectively. Today, RCM remains a fundamental principle in modern maintenance optimization, ensuring reliability while aligning with operational and economic goals.

The MSG Frameworks

The Maintenance Steering Group (MSG) methodology was developed to standardize and refine maintenance practices, integrating Reliability-Centered Maintenance (RCM) principles. Over time, the framework evolved through three generations—MSG-1, MSG-2, and MSG-3—each adapting to the increasing complexity of aircraft systems and improving maintenance efficiency.

The first iteration, MSG-1, introduced in 1968, provided a structured maintenance planning framework that categorized tasks into three types: Hard Time (HT), which required scheduled overhauls; On Condition (OC), involving inspections and performance tests; and Condition Monitoring (CM), which used operational data to determine maintenance needs. Despite its structured approach, MSG-1 was heavily reliant on fixed intervals, often leading to inefficiencies.

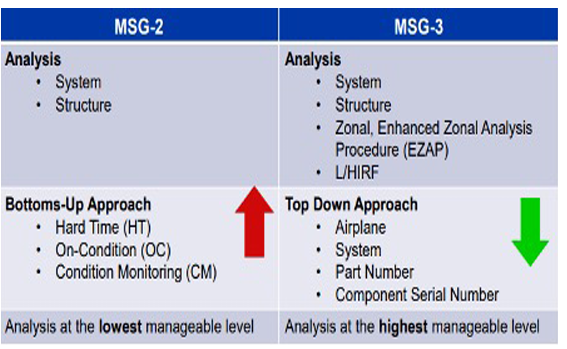

By 1970, MSG-2 built upon these foundations by emphasizing Condition Monitoring (CM), allowing real-time performance evaluations. This advancement reduced unnecessary replacements, as components were serviced only when they failed to meet operational standards, introducing greater flexibility in maintenance strategies.

The most significant shift came with MSG-3 in 1980, transitioning from a component-based to a system-centric approach. This framework embedded RCM principles and introduced key advancements, such as prioritizing hidden failures that might not immediately impact operations but could have severe consequences, adopting a task-oriented approach tailored to specific system needs, and utilizing a top-down analysis methodology for a more holistic assessment of aircraft maintenance requirements.

Today, MSG-3 remains the industry standard, shaping how modern maintenance programs are developed and ensuring optimal balance between safety, reliability, and cost-effectiveness.

Modern Maintenance Optimization Practices

Technological advancements have driven maintenance optimization beyond traditional MSG frameworks, leveraging data analytics and predictive modeling to enhance efficiency. Today, real-time monitoring systems, digital simulations, and data-driven optimization techniques play a pivotal role in shaping modern maintenance strategies.

Airplane Health Monitoring (AHM)

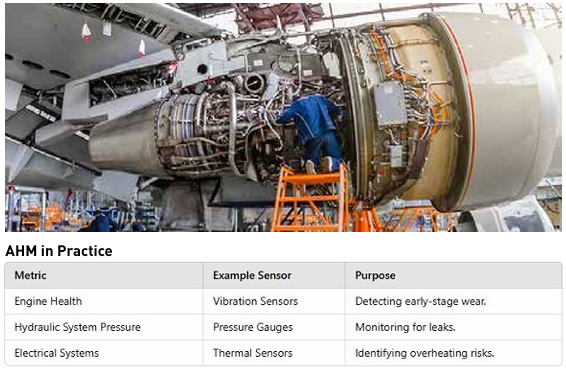

Airplane Health Monitoring (AHM) systems integrate sensors throughout an aircraft to collect real-time performance data. These systems track critical metrics such as engine performance, oil pressure, and environmental stress, enabling Condition-Based Maintenance (CBM) by scheduling tasks only when data indicates potential failures. This predictive approach reduces unscheduled downtime, enhances operational efficiency, and optimizes fleet utilization.

Digital Twins

Digital twins replicate physical aircraft within virtual environments, allowing operators to simulate real-world conditions. These virtual models predict component failures and wear, optimize maintenance intervals based on usage patterns, and test different operational scenarios without affecting actual aircraft. For instance, a digital twin of an aircraft engine can simulate its performance under varying loads, providing early insights into potential maintenance needs and improving lifecycle management.

System Analysis and Safety Monitoring Optimization (SASMO)

System Analysis and Safety Monitoring Optimization (SASMO) tools utilize historical maintenance records and operational data to refine task intervals. By identifying inefficiencies and trends, these tools help extend non-critical task intervals and optimize critical inspections to enhance safety and reliability. SASMO methodologies enable data-driven decision-making, ensuring that maintenance actions align with operational demands while minimizing costs and resource usage.

SASMO methodologies enable data-driven decision-making, ensuring that maintenance actions align with operational demands while minimizing costs and resource usage.

The integration of these advanced maintenance optimization techniques represents a significant shift from reactive to proactive strategies, ensuring improved aircraft reliability, reduced operational disruptions, and greater cost efficiency across the aviation industry.

Statistical Insights into Maintenance Optimization

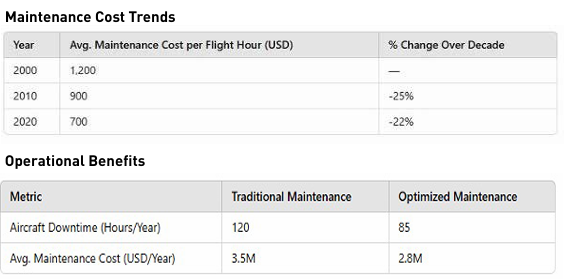

The adoption of advanced maintenance practices has led to measurable improvements in safety, cost savings, and operational efficiency.

The Future of Maintenance Optimization

The next stage in aircraft maintenance optimization lies in the integration of artificial intelligence (AI) and machine learning (ML), which promise enhanced efficiency, cost reduction, and improved safety. These technologies offer a transformative approach by automating processes, improving predictive accuracy, and dynamically adapting maintenance schedules.

Key Innovations in AI-Driven Maintenance

Predictive Analytics: AI can process vast datasets to forecast failures with greater accuracy than traditional methods, enabling more precise maintenance planning.

Autonomous Inspections: Drones and robotic systems can conduct rapid, high-precision inspections, reducing human workload and minimizing inspection times.

Dynamic Maintenance Scheduling:

ML algorithms can adjust maintenance schedules in real time based on operational demands, weather conditions, and aircraft usage patterns, ensuring optimal resource allocation.

AI in Predictive Maintenance

One of the most promising applications of AI in maintenance is predictive maintenance, where AI-powered systems analyze sensor data to detect microfractures in engine components before they lead to catastrophic failures. This proactive approach allows operators to replace parts preemptively, reducing unscheduled downtime, minimizing costs, and extending the lifespan of critical aircraft systems.As AI and ML continue to advance, their integration into maintenance strategies will revolutionize the aviation industry, making aircraft maintenance smarter, more efficient, and highly responsive to real-world operational challenges.

As outlined above, aircraft maintenance processes have undergone a significant transformation from traditional, rigid schedule-based methods to data-driven and dynamic approaches. The MSG-3 maintenance framework, Aircraft Health Monitoring Systems (AHM), and digital twins have enhanced maintenance strategies, making fleet management more precise and efficient.The future of the industry will be shaped by the widespread adoption of predictive maintenance tools powered by artificial intelligence (AI) and machine learning (ML). These innovations will provide real-time monitoring, autonomous inspections, and adaptive maintenance planning, reducing costs while enhancing safety and operational efficiency. With continuous technological advancements, the aviation industry will continue to move towards smarter, more proactive, and more reliable maintenance processes.