HUMAN FACTORS IN AIRCRAFT MAINTENANCE:

UNDERSTANDING AND MANAGING ERRORS

Aviation is one of the industries where safety must be maintained at the highest level. Modern aircraft are complex engineering marvels consisting of thousands of components, and each element must operate according to the highest safety standards. Additionally, ensuring safe and uninterrupted operations involves intricate maintenance processes. However, ensuring the safe operation of aircraft depends not only on technological systems but also on the people responsible for maintenance, repair, and inspection processes.

Human factors play a crucial role in aircraft maintenance. Maintenance technicians, engineers, and inspectors play a critical role in ensuring that aircraft meet operational requirements. Errors in aircraft maintenance do not only pose technical and operational risks but also result in significant economic losses. Engine failures, maintenance-related flight delays, and cancellations can cost airlines millions of dollars. So, how can we reduce human errors in maintenance processes and enhance safety? In an era of rapidly advancing technology, how can we integrate traditional maintenance practices with cutting-edge innovations?

This article examines the role of human factors in aviation maintenance, the most common types of errors, methods used to manage these errors, and how emerging technologies are being integrated into maintenance processes.

The Importance of Human Factors in Aircraft Maintenance

Human factors in aircraft maintenance analyze how technicians are affected by physical, psychological, and environmental conditions and how these factors impact their job performance. Maintenance processes often require technicians to work meticulously on complex systems under time constraints.

According to the Federal Aviation Administration (FAA), human errors in aircraft maintenance directly contribute to approximately 15% of aviation accidents. Studies conducted by the International Civil Aviation Organization (ICAO) indicate that a significant portion of these errors is directly linked to stress and time pressure experienced by maintenance technicians. The urgency of completing tasks on time can lead to overlooked procedures.

For example, in a Boeing study analyzing 122 maintenance errors, the errors were categorized into four main types:

Omissions: Skipping or forgetting a required maintenance step.

Example: A step in a test card being missed during maintenance, leading to unreliable results.

Improper Installations: Incorrect or incomplete installation of components.

Example: A missing washer on a bolt during a modification, causing extended parts to create damage.

Wrong Parts: Installing the wrong component or using a part incompatible with the aircraft model.

Example: Installing an incorrect component in an aircraft engine.

Other Factors: Incorrect documentation, procedural misapplication, and poor communication.

Example: Inadequate information transfer during shift changes, leading to major maintenance errors.

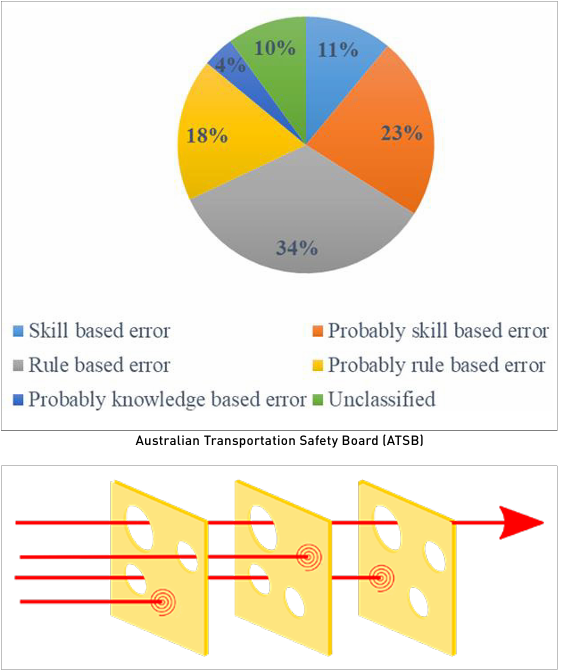

Another study categorizes human errors in aircraft maintenance into three main types based on technicians’ knowledge and skill levels:

Skill-based errors (48%)

Errors occurring due to routine tasks becoming automatic.

Example: An experienced technician assuming a different procedure is identical and performing the steps incorrectly.

Rule-based errors (28%)

Misapplying procedures or following incorrect rules.

Example: A technician not using the proper tool for component replacement.

Knowledge-based errors (24%)

Mistakes due to lack of experience or training.

Example: An experienced technician working on a new aircraft model without proper training, relying solely on past experience.

These classifications demonstrate that most maintenance errors originate from human factors and are largely preventable.

Many of these errors are due to improper working conditions, shift changes, fatigue, and lack of communication.

In addition, James Reason’s “Swiss Cheese” model, which classifies errors in more detail, shows that accidents are often caused by a combination of many small errors. Although there are many lines of defense in the system, mistakes can have serious consequences due to vulnerabilities in these lines of defense.

Accidents and Economic Impacts of Human Factors

Some of the largest aviation accidents in history were caused by maintenance errors:

American Airlines DC-10 Crash (1979)

On May 25, 1979, an American Airlines McDonnell Douglas DC-10 lost its left engine and pylon during takeoff from Chicago O’Hare Airport, leading to a crash. The root cause was a maintenance shortcut—instead of removing the engine and pylon separately, the maintenance crew removed them as a single unit to save time. This caused microscopic cracks in the pylon attachment points, which later failed during flight. 273 people lost their lives.

Japan Airlines Flight 123 (1985)

On August 12, 1985, a Japan Airlines Boeing 747 suffered a structural failure and crashed into a mountain, killing 520 people. The accident was caused by a faulty repair in 1978. Instead of following Boeing’s recommended repair procedure, a faster but incorrect repair was performed. Seven years later, metal fatigue led to the failure of the cabin pressure bulkhead, causing a loss of control.

Southwest Airlines Flight 1380 (2018)

On April 17, 2018, a Southwest Airlines Boeing 737 suffered an engine failure en route from New York to Dallas. A fan blade, weakened by metal fatigue, detached and struck the fuselage, shattering a window. A passenger was partially ejected and lost her life. The root cause was the failure to detect metal fatigue during maintenance inspections.

These incidents show how critical human factors are in aviation maintenance and that mistakes can have serious consequences. According to a cost analysis by Boeing, engine failures caused by maintenance errors cost an average of $500,000 per incident. In addition, delays caused by aircraft maintenance errors cost airlines an average of $10,000 per hour.

Methods of Preventing and Managing Errors in Aviation

Various strategies and programs have been developed in the aviation industry to minimize human errors and increase operational safety and efficiency. We can list them as follows.

1. Reactive Error Management (Result-Oriented Approach)

Reactive error management aims to analyze the errors and accidents that occur and to take measures to prevent similar incidents in the future. This approach involves making systematic improvements by learning from past events.

The main reactive error management tools are:

Accident and Incident Investigation Boards: National and international aviation authorities examine accidents and serious incidents in detail, conduct root cause analyzes and publish safety recommendations.

Error Reporting Systems: These are the systems that enable aviation personnel to report errors voluntarily or compulsorily. These reports are analyzed within the framework of confidentiality principles and help to identify systematic problems.

Internal Audit and Review: Aviation enterprises regularly review their operational processes and procedures, detect errors and take corrective measures through their internal audit mechanisms.

2. Proactive Error Management (Preventive Approach)

Proactive error management encompasses strategies to prevent failures before they occur. This approach focuses on the early identification and elimination of potential risks and hazards.

The main methods applied within the scope of proactive error management are as follows:

Risk Assessment and Management: Potential risks in operational processes are identified, analyzed and reduced to acceptable levels. This process involves a cycle of continuous monitoring and improvement.

Training and Awareness Programs: Raising awareness and training of staff on human factors is one of the cornerstones of proactive error management. Trainings enable staff to recognize and prevent potential mistakes.

Promotion of Communication and Teamwork: Effective communication and teamwork play a critical role in preventing mistakes. Creating clear communication channels ensures that team members work in harmony with each other.

3. Maintenance Resource Management (MRM)

Maintenance Resource Management (MRM) is a training and management program developed to reduce human errors in aircraft maintenance processes. MRM aims to improve team communication, leadership, situational awareness and decision-making processes.

The key components of the MRM program are:

Intra-Team Communication: Effective communication increases the coordination of maintenance teams and helps prevent mistakes.

Leadership and Decision Making: Leadership skills and correct decision-making processes increase the effectiveness of maintenance operations.

Situational Awareness:

The ability of staff to accurately assess the current situation and anticipate potential risks is critical in preventing mistakes.

Stress and Fatigue Management: Stress and fatigue can negatively affect human performance. MRM offers strategies for managing these factors.

4. Human Factors Analysis and Classification System (HFACS)

HFACS is a model developed to analyze and classify human errors. This system examines errors at four main levels:

Safety Culture and Organizational Factors: The organization’s general understanding of security, policies and procedures.

Audit and Management Practices: Audit and control mechanisms of the management level.

Environmental and Situational Factors: Working environment, equipment condition and environmental conditions.

Individual Mistakes: Individual mistakes of the staff, such as lack of knowledge, inexperience, or carelessness.

The implementation of HFACS helps organizations better understand the root causes of human errors and take preventative measures accordingly.

5. Technological Support and Automation

With the development of technology, various automation and support systems have been developed to reduce human errors in maintenance processes. These systems provide guidance to maintenance personnel and help detect potential errors in advance.

Prominent technological supports include:

Digital Maintenance Manuals and Checklists: Traditional paper-based maintenance manuals and checklists are based on manual processes that are prone to human error. Digitalization offers a huge opportunity to make maintenance processes more reliable. Electronic maintenance manuals ensure technicians have access to the most up-to-date procedures and prevent the use of incorrect documentation. Digital systems integrated with mobile tablets and smart devices in aviation allow maintenance records to be kept accurately. Aircraft manufacturers and airlines use these systems to avoid the wrong selection of components or procedures.

For example; Lufthansa Technik and Boeing are expanding electronic maintenance management systems (e-Maintenance Systems), which allow technicians to digitally control every maintenance step. Thanks to these systems, the use of wrong parts or incomplete maintenance procedures are detected and warnings are given.

Augmented Reality (AR) and Virtual Reality (VR) Based Training: One of the biggest challenges for aviation maintenance technicians is being able to repair complex systems without errors and quickly adapt to new aircraft models. Augmented reality (AR) and virtual reality (VR) help technicians manage these processes more efficiently and accurately. AR-based maintenance systems enable technicians to accurately repair complex components with live guidance. VR simulations make it possible for technicians to learn maintenance procedures without risk and practice before making mistakes in the real world. For example; Airbus and Boeing have developed VR-based training systems for maintenance technicians. Airbus’ “HoloLens” project provides technicians with real-time AR-powered maintenance processes, minimizing errors.

Artificial Intelligence (AI) Assisted Maintenance and Predictive Maintenance: Artificial intelligence and big data analytics offer innovations that can revolutionize aircraft maintenance. Traditional maintenance methods are usually based on reactive or scheduled maintenance, but predictive maintenance reduces the risk of errors by ensuring that components are replaced before they fail. Sensors predict maintenance requirements by collecting real-time data from engines, hydraulic systems, and flight computers. AI-based analytics guide technicians by identifying maintenance requirements and prevent misdiagnoses. For example; Rolls-Royce’s “Engine Health Monitoring” system analyzes the operating data of aircraft engines, predicts potential failures in advance and reports them to airlines, GE Aviation and Pratt & Whitney have developed artificial intelligence-supported engine analysis systems, increasing the prediction rate of failures by 30%

Robotics and Automated Fault Detection Systems: Robots are increasingly being used to minimize human-induced maintenance errors. In particular, unmanned aerial vehicles (drones) and climbing robots are used to identify cracks, paint abrasions and structural defects on aircraft surfaces that are difficult to detect with the naked eye. Drones can scan airframes to detect surface damage and paint wear. Autonomous robots can perform inspection of complex parts such as landing gear and engine components.

For example, Airbus has developed an AI-powered system that automatically examines airframes with advanced maintenance drone systems. Magnetic climber robots developed by Invert Robotics have reduced maintenance times by 50% by detecting cracks in areas that technicians cannot reach.

Blockchain-Based Maintenance Records: Blockchain technology is used to ensure that aircraft maintenance records are secure and immutable. In traditional maintenance record systems, it is possible for records to be altered or updated with incorrect information, but blockchain-based systems reduce the risk of errors by making the maintenance history transparent and secure. All maintenance operations are stored in encrypted and verifiable blocks. Airlines can prevent transactions with incorrect information by detecting erroneous records in maintenance processes. Honeywell Aerospace has announced that it has reduced transcription errors by 40% by storing the maintenance history of aircraft components in a blockchain-based system.

New technologies and error management systems developed to minimize human errors in aviation maintenance make the industry safer and more efficient. Digitalization, artificial intelligence, augmented reality, and automation technologies are among the most important tools to help prevent errors caused by human factors. In the coming years, blockchain-based maintenance records, predictive maintenance systems, and robot-assisted inspections will become widespread in the aviation maintenance industry, greatly reducing human errors.