BITE TEST:

THE EYES AND EARS OF AVIATION MAINTENANCE

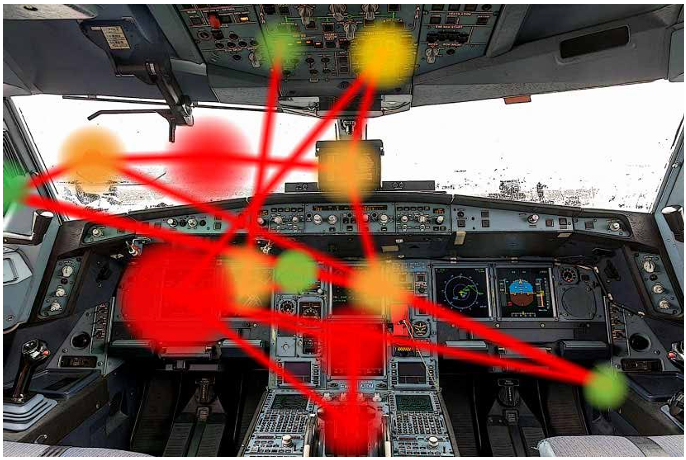

In a modern aircraft cockpit, hundreds of buttons, screens, and systems work together to ensure a safe flight. But how do we know if each of these systems is functioning correctly? Detecting faults in avionics systems before they escalate into major issues is a critical aspect of aviation maintenance. This is where BITE (Built-In Test Equipment) testing comes in, playing a crucial role in keeping aircraft systems operational and ensuring flight safety.

The Origins of BITE Testing: Why Was It Developed?

In the early days of aviation, troubleshooting faults relied heavily on manual inspections and visual checks by technicians. However, as aircraft became more complex—especially with the introduction of jet engines and sophisticated avionics—these traditional methods proved insufficient.

By the 1960s, military aviation recognized the need for automated diagnostic systems to minimize maintenance time and quickly detect system failures. Military jets, designed for rapid deployment and operational readiness, required self-diagnostic capabilities to identify malfunctions without extensive manual inspections. This necessity led to the development of BITE systems, which could conduct internal system checks and provide real-time feedback on potential issues.

The Evolution of BITE Testing in Commercial Aviation

Following its success in military aircraft, BITE technology was integrated into commercial aviation. By the 1980s, aircraft manufacturers such as Boeing and Airbus began incorporating built-in test capabilities into their avionic systems.

Modern aircraft, like the Airbus A320 and Boeing 737, come equipped with advanced BITE systems that constantly monitor avionics, flight control, and engine health. These systems can detect and diagnose issues ranging from minor sensor malfunctions to critical failures in electronic components.

How Does BITE Testing Work?

BITE testing is essentially an onboard diagnostic system that runs self-tests on aircraft components. The process involves three main functions:

Fault Detection: Identifying anomalies or deviations from standard performance.

Fault Isolation: Pinpointing the exact component or subsystem responsible for the issue.

Fault Reporting: Storing diagnostic data for use by maintenance crews, allowing them to assess the issue quickly.

When a BITE system detects a problem, it generates a fault code, which is recorded in the aircraft’s maintenance log. Technicians can then use specialized diagnostic tools, such as a Central Maintenance Computer (CMC), to analyze these fault codes and determine the necessary corrective actions.

Applications of BITE Testing in Modern Aviation

1. Routine Maintenance and Pre-Flight Checks

BITE tests are regularly conducted as part of pre-flight and post-flight inspections to ensure that all critical systems are functioning properly. Airlines rely on these tests to minimize the risk of in-flight failures and to comply with aviation safety regulations.

2. Troubleshooting System Malfunctions

When pilots report a system malfunction during flight, BITE diagnostics provide the first line of troubleshooting. For example, if a navigation display fails, a BITE test can confirm whether the issue stems from the display unit itself, a faulty data connection, or an underlying software error.

3. Predictive Maintenance and Data Analytics

With the rise of big data and predictive analytics, BITE testing is no longer just about identifying current faults—it is also used to predict potential failures before they occur. By analyzing trends in BITE data over time, airlines can proactively replace components that are likely to fail, reducing unplanned maintenance and improving aircraft availability.

4. Compliance with Aviation Regulations

Regulatory agencies such as the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency) require periodic system checks, many of which rely on BITE diagnostics. Ensuring compliance with these regulations is essential for maintaining aircraft certification and operational safety.

Challenges and Limitations of BITE Testing

While BITE testing has revolutionized aircraft maintenance, it is not without challenges:

False Positives & Negatives: Sometimes, a BITE system may generate an error code for a problem that does not exist (false positive) or fail to detect an actual issue (false negative).

Complex Interpretation: Modern aircraft systems are highly interconnected, making it difficult to interpret some BITE test results without further manual inspection.

Dependence on System Health: If the BITE system itself malfunctions, it may not accurately report issues, leading to potential misdiagnoses.

The Future of BITE Testing: AI and IoT Integration

As aircraft become increasingly connected through the Internet of Things (IoT), BITE testing is evolving into a more advanced predictive maintenance tool. Future advancements include:

Artificial Intelligence (AI)-Driven Diagnostics: AI can enhance BITE testing by learning from historical data and identifying subtle patterns that may indicate early-stage system degradation.

Remote Monitoring & Cloud-Based BITE Analysis: Airlines are exploring real-time, cloud-based monitoring of BITE data, allowing maintenance teams to assess aircraft health while in-flight and prepare for necessary repairs before landing.

Augmented Reality (AR) for Maintenance Crews: AR could provide technicians with visual overlays of BITE test results, helping them quickly locate and resolve faults.

Conclusion

BITE testing has become an essential part of aviation maintenance, enhancing operational efficiency, safety, and reliability. What began as a tool for military aircraft has now become a standard feature in modern commercial aviation, ensuring that every flight is as safe as possible. As technology continues to evolve, BITE systems will play an even greater role in predictive maintenance, reducing downtime and keeping aircraft in peak operational condition.

With advancements in AI, IoT, and data analytics, the future of BITE testing is set to redefine how airlines approach aircraft maintenance—proactively addressing potential failures before they occur and making air travel even safer than ever before.